Jervois completes U.S. Department of Defense reimbursed drilling at ICO’s Sunshine deposit

(TheNewswire)

Highlights:

-

-

2.9m calculated true width (“CTW”) @ 0.01% cobalt

(“Co”), 0.27% copper (“Cu”), 0.03 grams per metric tonne

(“g/t”) gold (“Au”) (Drillhole SS23-01A)

-

1.2m CTW @ 0.34% Co, 10.05% Cu, 13.68 g/t Au (Drillhole

SS23-02)

-

1.7m CTW @ 0.68% Co, 0.35% Cu, 0.51 g/t Au (Drillhole

SS23-03)

-

0.5m CTW @ 1.55% Co, 0.02% Cu, 1.30 g/t Au (Drillhole

SS23-04)

-

2.6m CTW @ 0.78% Co, 0.12% Cu, 0.41 g/t Au (Drillhole

SS23-05)

-

3.2m CTW @ 0.05% Co, 0.89% Cu, 0.07 g/t Au (Drillhole

SS23-06A)

-

0.9m CTW @ 0.07% Co, 1.10% Cu, 0.03 g/t Au (Drillhole

SS23-07)

-

-

Cobalt has been declared by the U.S. Government a

critical mineral, and a reserve or price floor to sustain domestic

American production has been put forward by the U.S. Congressional

Select Committee on the Chinese Communist Party (see Jervois ASX

announcement dated 13 December 2023, “Jervois welcomes U.S.

Congressional Select Committee proposal for a reserve to sustain

cobalt price”)

30 January 2024 –

TheNewswire

–

Australia – Jervois Global Limited

(“

Jervois

” or the

“

Company

”)

(

ASX:

JRV) (

TSXV:JRV

)

(OTC:JRVMF)

Jervois Global Limited

(“

Jervois

” or the

“

Company

”) (ASX: JRV)

(TSX-V: JRV) (OTC: JRVMF) is pleased to report results from its

inaugural Sunshine drilling campaign at its Idaho Cobalt Operations

(“

ICO

”) in Idaho,

United States (“

U.S.

”).

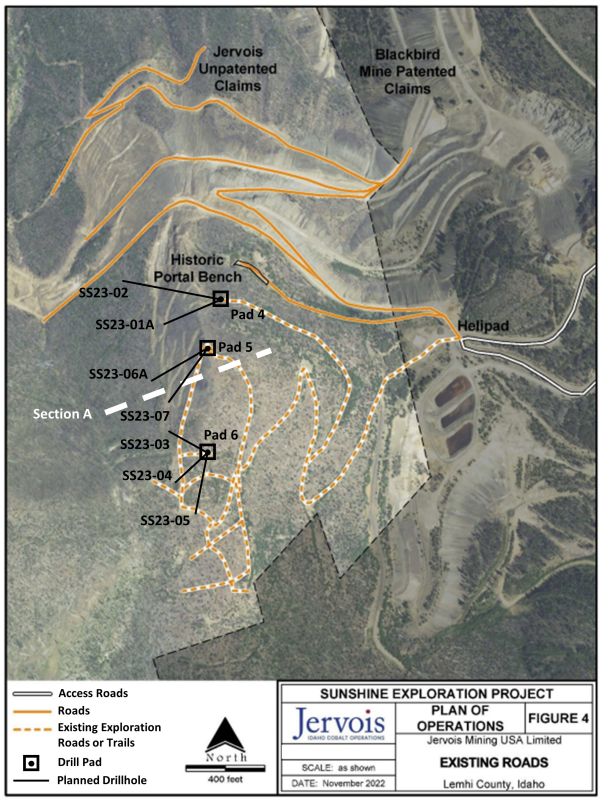

Collar information is provided in Table 1, along with

tabulated analytical results (Table 2), a plan view map showing drill

pad locations (Figure 1) and a cross-sectional overview of drilling

methodology (Figure 2).

Uncapped drill results include:

-

Hole SS23-01A intersected 2.9m CTW at 0.01% Co, 0.27%

Cu, 0.03 g/t Au.

-

Hole SS23-02 intersected 1.2m CTW at 0.34% Co, 10.05%

Cu, 13.68 g/t Au. In addition, mineralization was encountered in the

hanging wall (

HW

”) to

the Sunshine mineralized horizon, grading 0.42% Co, 0.18% Cu, 0.10 g/t

Au across 1.0m CTW.

-

Hole SS23-03 intersected 1.7m CTW at 0.68% Co, 0.35%

Cu, 0.51 g/t Au.

-

Hole SS23-04 intersected 0.5m CTW at 1.55% Co, 0.02%

Cu, 1.30 g/t Au. Again, additional, mineralization was encountered in

the footwall (

FW

”) to

the Sunshine mineralized horizon, grading 0.15% Co, 0.71% Cu, 0.03 g/t

Au across 2.2m CTW.

-

Hole SS23-05 intersected 2.6m CTW at 0.78% Co, 0.12%

Cu, 0.41 g/t Au.

-

Hole SS23-06A intersected 3.2m CTW at 0.05% Co, 0.89%

Cu, 0.07 g/t Au.

-

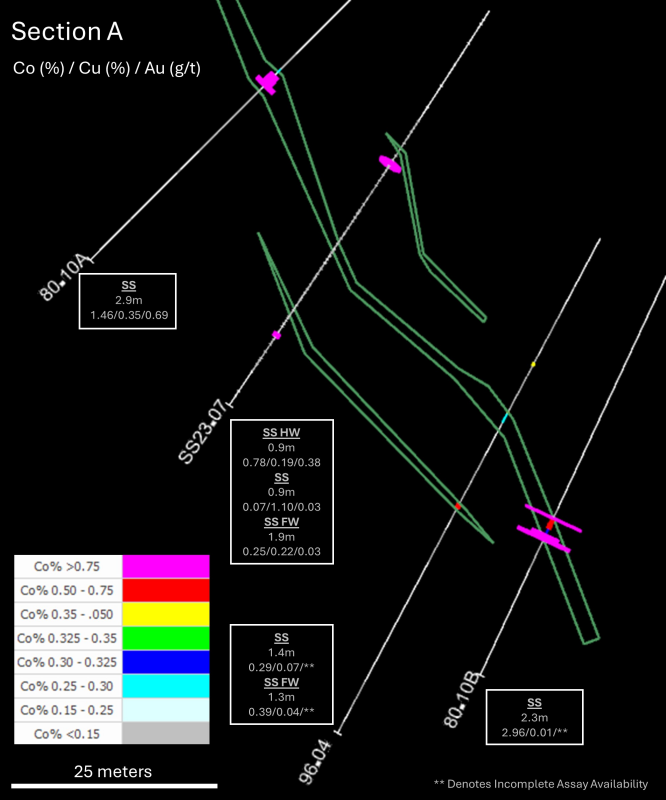

Hole SS23-07 intersected 0.9m CTW at 0.07% Co, 1.10%

Cu, 0.03 g/t Au. In addition, mineralization was encountered in the HW

to the Sunshine mineralized horizon, grading 0.78% Co, 0.19% Cu, 0.38

g/t Au across 0.9m CTW, as well as in the FW to the Sunshine

mineralized horizon, grading 0.25% Co, 0.22% Cu, 0.03 g/t Au.

These drilling results will be utilized to confirm

historic drill intercepts, comprised of 19,000m (104 drillholes) of

core drilling, within the Sunshine deposit and be incorporated

alongside within an updated Australian JORC / Canadian CIM compliant

Sunshine Mineral Resource Estimate (“

MRE

”).

ICO continues with the resource extension programme at

its RAM deposit (see ASX announcement dated 20 November 2023,

“Jervois commences U.S. government-funded resource extension

programme at ICO’s RAM deposit”).

Based on the existing U.S. DoD US$15.0 million

Agreement Funding, costs for these exploration programmes, up to the

end of Q3 2024 for exploration development, drilling, logging,

assaying, MRE modelling and Jervois programme supervision, are fully

reimbursed. The Agreement Funding is under the Manufacturing

Capability Expansion and Investment Prioritization office of

Industrial Base Policy using the U.S. DPA Title III authorities and

utilises funds from the Additional Ukraine Supplemental Appropriations

Act.

Table 1: Sunshine Drillhole Collars

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*

Coordinates provided in Mine

Grid of RAM Deposit.

**

Drill hole abandoned

prior to mineralized intersection

Table 2: Sunshine Drilling Results

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* Sunshine (SS), Sunshine Hangingwall (SS HW), Sunshine

Footwall (SS FW)

** Calculated true widths determined for the composited

intercept mid-point, perpendicular to the down-dip projection of the

Sunshine deposit target models derived from historic Sunshine

drilling

Note:

All grades are reported

uncut for all zones

Figure 1: Sunshine Drill Pad Locations

Figure 2: Sunshine Section A Showing SS23-07 in

Relation to Historic Drill Intercepts

Quality Assurance

Jervois sent all drill core samples to ALS Global

Laboratories (Geochemistry Division), an independent and fully

accredited laboratory (ISO 9001:2008), in Vancouver, Canada, for

analysis for gold by Fire Assay and multi-element Induction Coupled

Plasma Spectroscopy.

Jervois employs a regimented Quality Assurance, Quality

Control (“

QA/QC

”)

program where at least 10% duplicates, blanks and certified reference

material are inserted into each sample shipment.

On behalf of Jervois Global Limited

Bryce Crocker, Chief Executive Officer

For further information, please contact:

Competent Person’s Statement

The information in this release that relates to Mineral

Exploration is based on information compiled by Andrew Turner, P.Geol.

who is a consultant for the company and a member of The Association of

Professional Engineers and Geoscientists of Alberta. Andrew Turner

has sufficient experience which is relevant to the style of

mineralisation and type of deposit under consideration and to the

activity which he is undertaking to qualify as a Competent Person as

defined in the 2012 Edition of the ‘Australasian Code for Reporting

of Exploration Results, Mineral Resources and Ore Reserves’.

Andrew Turner consents to the inclusion in the release of the

matters based on the information in the form and context in which it

appears.

Qualified Person’s Statement

The technical content of this news release has been

reviewed and approved by Andrew Turner, P.Geol., a consultant for the

Company and a Qualified Person as defined by National Instrument

43-101.

Forward-Looking Statements

This news release may contain certain

“Forward-Looking Statements” within the meaning of the United

States Private Securities Litigation Reform Act of 1995 and applicable

Canadian securities laws. When used in this news release, the words

“anticipate”, “believe”, “estimate”, “expect”,

“target, “plan”, “forecast”, “may”, “schedule”,

“expected” and other similar words or expressions identify

forward-looking statements or information. These forward-looking

statements or information may relate to the timing of drilling

operations at ICO, the outcome of the drilling program, timing of an

updated resource model and certain other factors or information. Such

statements represent Jervois’ current views with respect to future

events and are necessarily based upon a number of assumptions and

estimates that, while considered reasonable by Jervois, are inherently

subject to significant business, economic, competitive, political and

social risks, contingencies and uncertainties. Many factors, both

known and unknown, could cause results, performance or achievements to

be materially different from the results, performance or achievements

that are or may be expressed or implied by such forward-looking

statements. Jervois does not intend, and does not assume any

obligation, to update these forward-looking statements or information

to reflect changes in assumptions or changes in circumstances or any

other events affections such statements and information other than as

required by applicable laws, rules and regulations.

Neither TSX Venture Exchange nor its Regulation

Services Provider (as that term is defined in policies of the TSX

Venture Exchange) accepts responsibility for the adequacy or accuracy

of this release.

Appendix 1:

JORC Code, 2012 Edition – Table 1

Section 1 Sampling

Techniques and Data

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Section 2 Reporting of

Exploration Results

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright (c) 2024 TheNewswire – All rights reserved.